Control up to 4 print heads simultaneously with 1 unit.

Saves space by combining multiple controllers into 1 unit.

Print heads with different resolutions can be controlled simultaneously for a single print object.

- ・By combining the controllers required for each head one at a time, the work efficiency is greatly improved.

- ・Space saving around the conveyor.

- ・Maximum of 4 heads can be controlled per 1 controller.

- ・It is also possible to simultaneously control high resolution head and low resolution head for one work.

Corresponding head

2558ch head

510ch head

1200ch head

384ch head

256ch head

256ch head

M800

| Printing system | |||||

|---|---|---|---|---|---|

| Piezo | Piezo | thermal | Piezo | Piezo | Piezo |

| Number of heads | |||||

| Up to 4 | Up to 4 | Up to 4 | Up to 4 | Up to 4 | Up to 5 |

| Print height in mm | |||||

| 108mm | 70mm | 49.3mm | 32.4mm | 130mm | 56.2mm |

| Number of channels | |||||

| 2558 | 510 | 1200 | 384 | 256 | 800 |

| Resolution in dpi | |||||

| 600dpi | 180dpi | 600dpi | 300dpi | 50dpi printhead in upright position |

360dpi |

| Printing speed in m/min | |||||

| 50 | 67 | 30 | 40 | 152 | 60 |

| Ink jetting direction | |||||

| horizontal or downward |

horizontal or downward |

horizontal or downward |

horizontal or downward |

horizontal or downward |

horizontal or downward |

Inks

| oil based | UV curable | water based | alcohol based | Solvent based, printing styrofoam |

|

|---|---|---|---|---|---|

| Head with 2258 ch(Y2558) | black | black, magenta, cyan and yellow |

NA | NA | NA |

| Head with 510 ch(S510) | black, red and blue | NA | NA | NA | NA |

| Head with 1200 ch(H1200) | NA | NA | black | black | NA |

| Head with 384 ch(R384) | black | NA | NA | NA | NA |

| Head with 256 ch(K256) | black | NA | NA | NA | black, red, blue, green |

Controller specification

Multi-controller

| Number of print lines | No limit (any lines you can print as long as the font size is within the appropriate range) |

|---|---|

| Number of messages stored | Up to 9,999 messages |

| Printable characters | alphanumerical, signs, Japanese Hirakana, Katakana and Kanji and the fonts listed in the Windows fonts |

| Date, time printing | Year (Christian calendar year or Japanese calendar year)/month/date/time (12/24 hours)/minute/second and day of the week |

| Numbering | Up to 10 digits, up/down, repetition, increased value settable, zero-suppression, assigned character printing |

| Barcode | ITF, Code39, Code128, NW-7, JAN/EAN, GS1 data bar |

| 2D code | QR, Data Matrix and PDF417 |

| Graphics | Captured images in the BMP, JPG or PNG format, straight line, square line or circle line |

| External interface | USB memory, digital I/O, rotary encoder or RS232C and LAN |

| Operational environment | required 5 to 35 degrees C., 10 to 80% RH with no dew condensation |

| Power supply | AC100V ± 10%, 50/60 Hz and 1000W or lower |

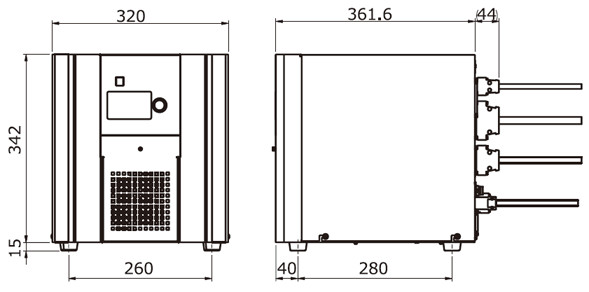

Dimensional drawing

A space of 250 mm in depth is required on the back of the controller for the cable connection